HTCure™ for robust Cobolt laser manufacturing

Cobolt’s advanced manufacturing technique can provide reliability and performance for today’s demanding applications.

Solid-state lasers are known to offer much extended lifetime as compared to gas lasers thanks to the lack of problems associated with the nature of a gaseous lasing medium. However, this advantage can not be realised in practice if the laser assembly in itself is neither extremely stable over time nor insensitive to thermal and mechanical shocks or vibrations. The introduction of High Temperature Curing or HTCure™ technology, a proprietary method for fixation of cavity components developed by Cobolt, provides a solution to this problem and has established a new level of reliability for advanced solid-state lasers.

The HTCure™ technology is based on building the lasers into a hermetically sealed sub-package in a planar configuration. The material and design of each component in the architecture has been carefully chosen for extremely high overall thermo-mechanical stability. As a result, the design is so thermo-mechanically stable that the whole laser can be baked at >100° C for several hours and at multiple phases as part of the manufacturing process without the laser going out of alignment or any damage being caused.

This extraordinary capability of the design has enabled the use of a new advanced type of adhesive for the fixation of cavity components that cures at high temperatures, instead of the traditional UV curing fixation methods. Thermal curing yields a very stiff and reliable fixation joint, free from outgassing and the long-term drifts sometimes associated with curing using UV light.

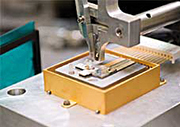

Pre-assembly of Cobolt 04-01 lasers prior to permanent fixation using HTCure ™ technology

Active alignment of optical components with sub-um precision on the Cobolt 04-01 laser platform

Cobolt 04-01 laser package

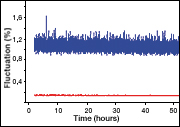

Typical noise stabillity of Cobolt

04-01 lasers

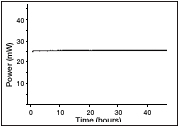

Typical power stability of Cobolt

04-01 lasers