Laser-induced breakdown spectroscopy (LIBS)

Laser-induced breakdown spectroscopy (LIBS) is an atomic-emission spectroscopy technique that enables rapid chemical analysis of a wide range of materials ranging from metals, semiconductors, glasses, biological tissues, plastics, soils, thin-paint coating, and electronic materials.

The principles of LIBS

LIBS is very ppowerful analytical technique that helps determine the elemental composition of a wide range of samples. In principle it relies on focusing short and high energy laser pulses onto the surface of a target sample to generate a plasma of small amounts of ablated material. The extremely high temperatures within the plasma causes the ablated material to dissociate into excited atomic and ionic species. Once the cooling process is completed, the characteristics of the sample can be detected by a spectrograph.

LIBS has received substantially increased interest over recent years as a result of the development of more compact, even hand-held, systems that enables in-field use and construction of tools for on-line material analysis.

Laser performance in LIBS imaging

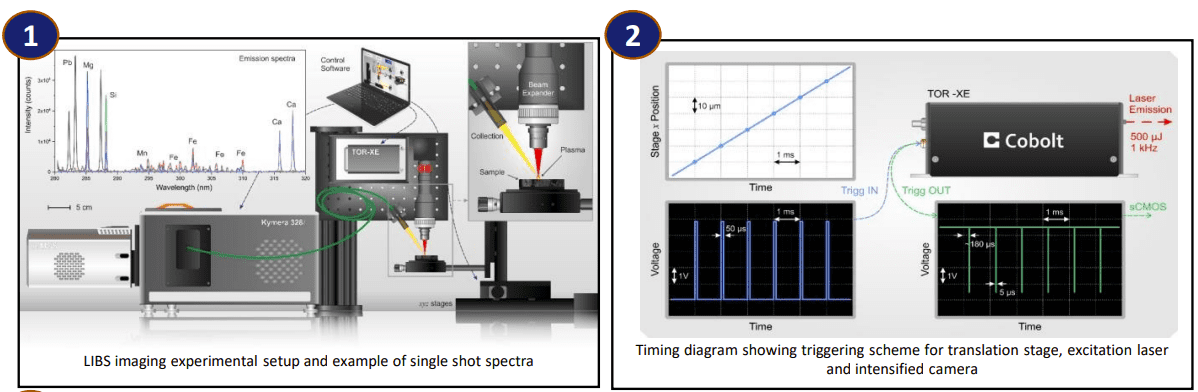

Within the realm of µ-LIBS (micro-LIBS) imaging, laser performance is pivotal for optimal results. This technique hinges on systematically scanning a sample with a focused laser beam, enabling the acquisition of a LIBS spectrum with each pulse or shot at various spatial positions across the sample surface.

The LIBS spectrum is characterized by multiple emission lines, from which interference-free lines are selected for analysis. These specific spectral lines within the collected LIBS spectra are element-specific, facilitating the reconstruction of elemental maps or the distribution of chemical elements within the analyzed sample area.

µ-LIBS imaging offers not only qualitative insights into the sample but also quantitative information. Quantitative analysis, manifested in image contrast, relies on associating spectral intensity with element concentration through univariate or multivariate models.

In the context of LIBS systems, the choice of laser for material ablation is crucial. The repeatability of LIBS measurements directly correlates with laser performance, as plasma generation depends on nonlinear processes. Fluctuations in laser parameters such as pulse energy, pulse duration, and beam quality can result in variations in ablated mass, plasma temperature, and electron density. These fluctuations are reflected in the plasma emission spectrum, potentially leading to analytical inaccuracies.

The importance of laser performance is amplified in µ-LIBS imaging, where raster scanning of the sample typically involves a single laser pulse per acquisition data point. The quality of the laser beam directly influences the ability to tightly focus it into a spot, defining the spatial resolution of the system and the minimum pixel size of an image. Additionally, the repetition rate of the laser determines the maximum acquisition/scanning speed available. While this parameter may be less critical in many LIBS applications requiring only a few hundred laser shots for analysis, in high-resolution µ-LIBS imaging over significant sample areas, up to 1 million spectra per cm2 may be collected. Consequently, recording an area of a cm2 with µm-resolution using a 10–40 Hz laser could take anywhere from 3–15 hours.

Advancements in High-Resolution LIBS Imaging

Traditionally, LIBS imaging instruments leverage lasers with repetition rates below 100 Hz, striking a balance between sampling frequency and laser pulse energy. However, conducting high-resolution imaging over large sample areas (typically several cm2), at this frequency proves time-consuming due to the need to collect millions of spectral data points for image creation, which can take approximately 3–15 hours per cm2.

In a groundbreaking study by Tercier et al. (2023), a pioneering approach is introduced to significantly reduce acquisition time for high-resolution LIBS imaging. Their research unveils a novel µ-LIBS imaging microscope capable of achieving an astonishing 10 µm resolution in under 20 minutes per cm². This breakthrough marks the first time such high-resolution images can be captured, offering unprecedented insights into the intricate elemental distribution within analyzed samples.

The proposed µ-LIBS imaging system, illustrated in Figure 1, is a bespoke LIBS microscope centered on a compact nanosecond Nd:YAG passively Q-switched ring-cavity 1064 nm 1064 nm Cobolt Tor Series laser. With a pulse energy of 0.5 mJ and a pulse duration of 2.5 n, this system showcases remarkable efficiency and precision, revolutionizing the landscape of high-resolution LIBS imaging.

Advancing Aluminium Recycling with Compact LIBS Systems

Aluminium recycling stands as a prime example of an application poised to benefit significantly from more compact and industrial-grade LIBS systems. Aluminium, being inherently 100% recyclable, demands only 5% of the energy expended in extracting virgin minerals for its production. The potential for direct classification and sorting of recycled aluminium flows is immense, promising substantial economic benefits for aluminium producers while concurrently minimizing environmental footprints.

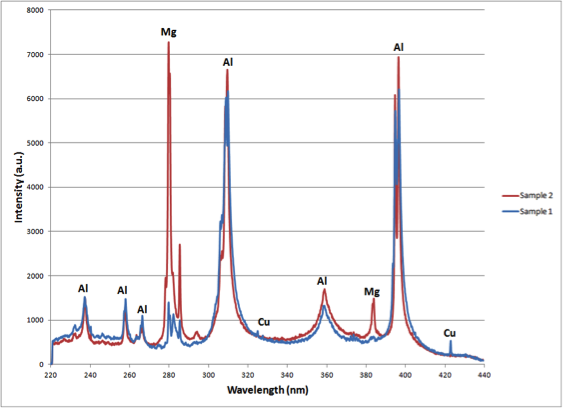

In a recent collaboration between researchers at ACREO and Kimab, a breakthrough was achieved by integrating a Cobolt Tor laser into a LIBS system. The objective was clear: to engineer a LIBS system that combines robustness with compactness, specifically tailored for industrial applications like aluminium recycling (FIG 2).

FIG 2. Field test of prototype LIBS system for automatic scrap metal sorting (Co ACREO AB, Stockholm, Sweden)

The Cobolt Tor lasers herald a new era with their compact design and high performance, effectively bridging the transition of LIBS systems from laboratory settings to industrial realms. These lasers are built on a proprietary design that offers a remarkable blend of stability, boasting a multi-kHz repetition rate (>7kHz with <1µs pulse-to-pulse jitter), pulse energies reaching the 100 µJ range at 1064 nm, pulse widths spanning a few ns, and exceptional beam quality (M2<1.3). Notably, the laser’s significantly smaller footprint compared to conventional high pulse energy Nd:YAG lasers is a standout feature. Moreover, its hermetically sealed packaging ensures enduring performance and longevity under diverse ambient conditions, rendering it highly adaptable for integration into demanding industrial settings.

LIBS experiments employing the Cobolt Tor laser were conducted on both Aluminium reference samples and dirty scrap samples procured from scrap yards. The results unequivocally demonstrate the system’s capability to accurately discern the elemental composition of various alloys, affirming the practical feasibility of a LIBS system anchored on compact, high repetition rate lasers.

FIG 2. LIBS data obtained with the Cobolt Tor pulsed 1064 nm laser from different scrap samples representing different aluminium alloys.

At HÜBNER Photonics we have lasers perfect for LIBS applications:

Cobolt Tor™ Series

High performance Q-switched lasers

Wavelength: 355, 532 and 1064 nm

Pulse energy: 50 – 500 uJ/pulse (Single pulse – 7 kHz)

Applications: LIBS, Maldi-TOF, Micro-machining & Marking

Publication – Tercier et.al High-Resolution High-Speed LIBS Microscopy, Spectroscopy (p.34) 2023

Poster – A novel platform for high speed, high resolution LIBS imaging SCiX 2022

Editorial – Lasers for fast and compact LIBS systems PhotonicsViews 2021

White paper – Compact, self-contained pulsed lasers expand capabilities in LIBS applications 2021

Editorial – Improved metal recycling using LIBS Physics’ Best 2016

Apps note – New compact high repetition rate lasers for LIBS

Compact, self-contained pulsed lasers expand capabilities in LIBS applications